We, Provide Professional Abrasives Production Solutions

SKD (Zhengzhou) Engineering Co., Ltd

Email: info@skdengineering.cn

Normal Rejected Products in Flap Disc Production

1. Reject Flap Disc by Safety Speed Test

Reject Flap Disc by Safety Speed Test

The flap disc passes the bursting test if it reaches the minimum bursting speed without breaking. if not, rejected.

Normally, the reject flap disc breaking is caused by unqualified fiberglass backing/plastic backing or glue bonding. The Testing Flap Disc(left picture) bursted when rotating at a speed, because the plastic backing material strength is not enough. The Flap Discs(right picture) broken caused glue bonding problem(glue bonding strngth is not enough or heating temperature control problem when baking in oven).

2. Reject Flap Disc caused by Sanding Cloth

The above two rejected flap discs are caused by defective Sanding Cloth Stripes. The Sanding Cloth Stirpe width is not even, some part is too wide or too narrow, this problems normally caused by Sanding Cloth Slitting Process.

Rejected Flap Disc(left picture): too narrow sanding cloth ribben at end.

Rejected Flap Disc(right picture): un-even wide sanding cloth ribben in middle.

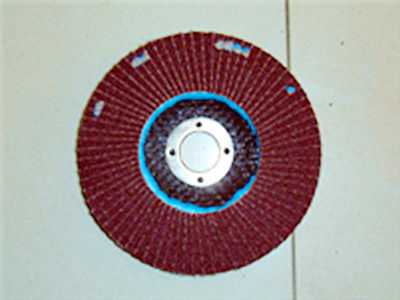

3. Reject Flap Disc caused by failure flaps arrangement

The above rejected flap disc is caused by failure flaps arranging, normally this fault is caused by flap disc machine problem, sanding cloth ribben has joint, glue is too hard, cut-blade is not sharp.

The above rejected flap disc is caused by flaps arranging deformation, the flap-circle is NOT ROUND. Normally this problem is caused by accidental impact.

The above rejected flap disc is caused by FLAP DROP(FLAP MISSING), normally this is caused by too low glue quantity, un-even glue application or some other carelessness.

4. Reject Flap Disc caused by Grinding Face Defect

The above rejected flap disc is caused by ABRASIVE LAYER MISSING, normally this is caused by too high glue quantity or un-even glue application, when baking, glue from higher flap disc flow down and several flap discs are stick together.