We, Provide Professional Abrasives Production Solutions

SKD (Zhengzhou) Engineering Co., Ltd

Email: info@skdengineering.cn

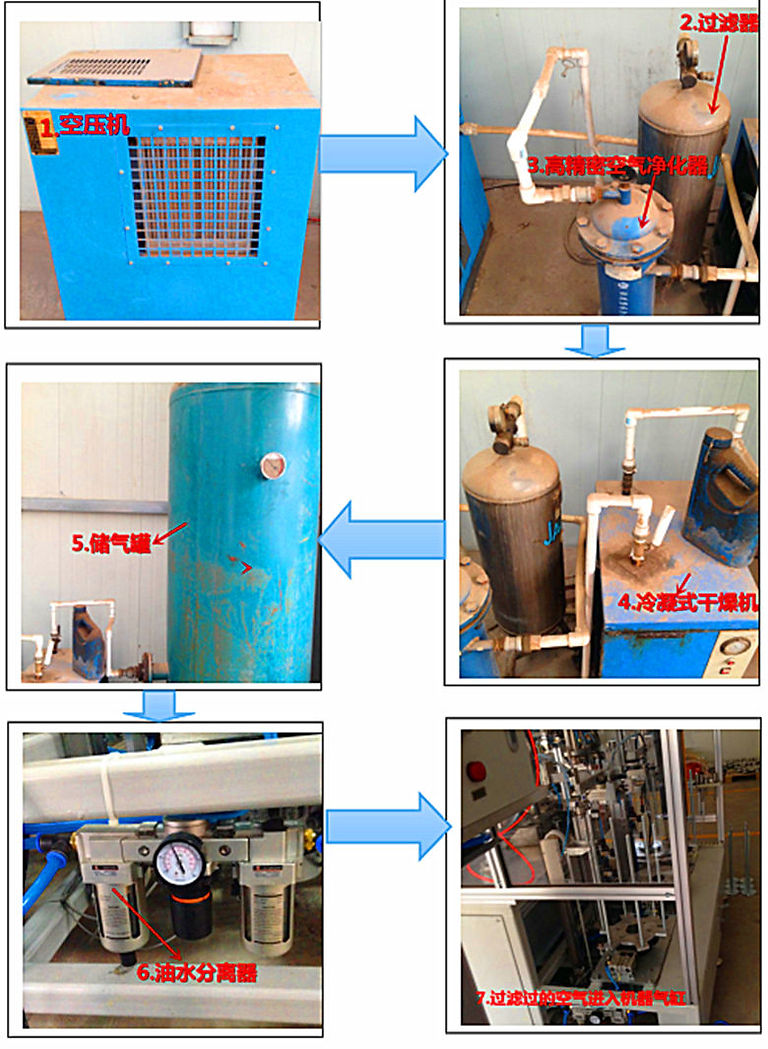

COMPRESSED AIR TREATMENT FOR FLAP DISC MACHINE

Simply Speaking,for flap disc machine, compressed air from air compressor should be treated to be clean and dry.

Dirt, water and oil in the compressed air, especially liquid water accelerates corrosion and shorten the use life of cylinders, valves,fittings and other pneumatic elements. Pneumatic cylinders of flap disc machine, grinding wheel production machine as the execute components working in a abrasive dusts room, the bad environment shorten the life time of cylinders,valves. If the compressed air source is also dirty and wet, the cylinder seals may wear out fast and need frequent maintenance.

So a clean, dry air supply can prevent many potential problems and result in lower operating costs in flap disc productions.

So a proper air treatment for flap disc machine should be:

1 Air Compressor ---- 2 Air Purifier --- 3 Condensing Dryer --- 4 Air Storage Tank --- 5 Water and Oil Separator